April showers may bring May flowers, but they also bring something that no one wants to deal with- mold.

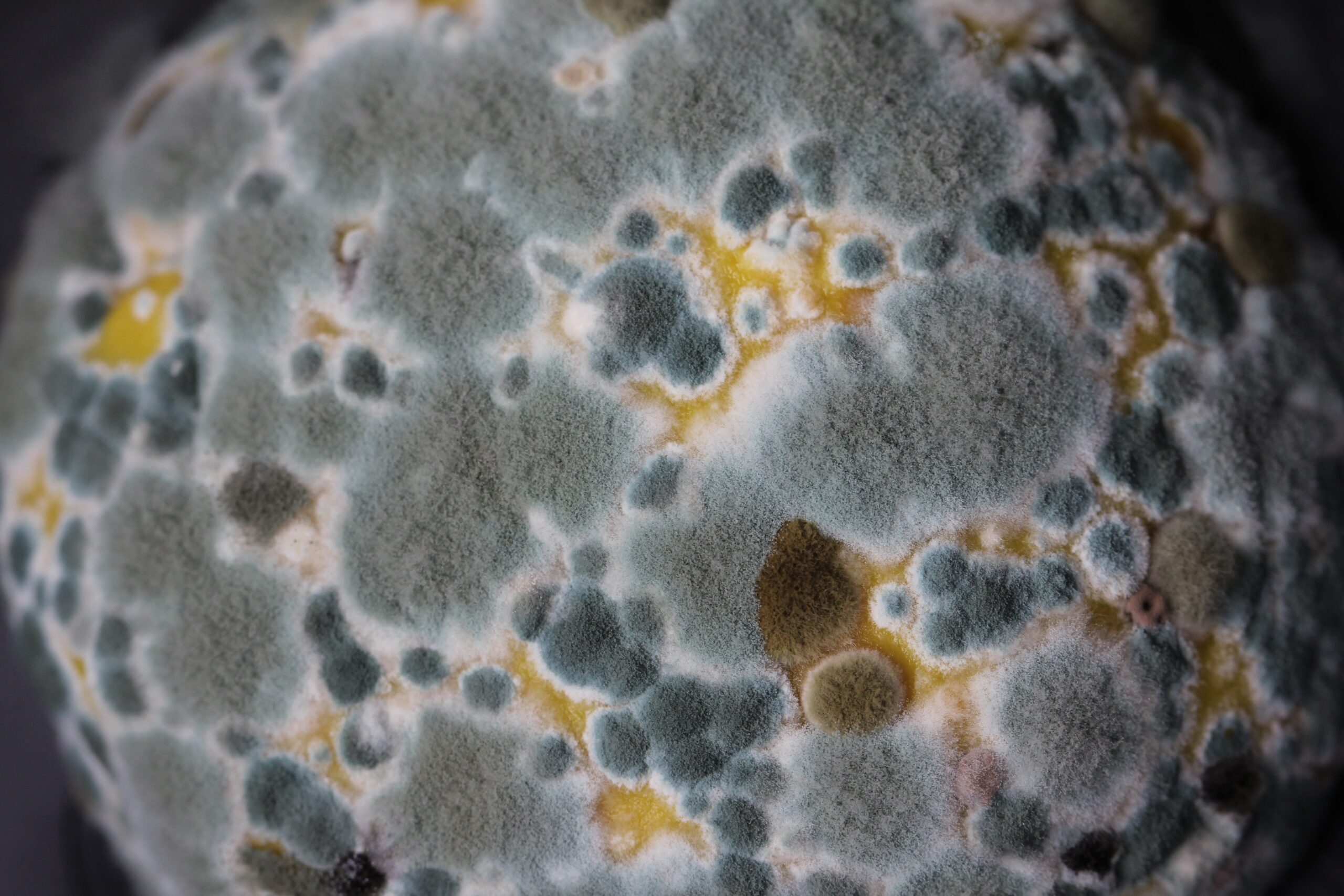

Mold is a type of fungus that produces pigmented spores and grows on the surface of wood products. Many different types of molds (thousands) can land on wood and begin to spread. Some of the types of molds are visible showing up in black, white, green, orange, or purple spots, while others might be invisible to the naked eye.

Mold is a common issue in the lumber industry and can affect the quality and durability of wood products, including pallets and crates if left unchecked. Anything made of wood is at risk of forming mold on it. Mold can grow on lumber during and after the manufacturing process, resulting in unsightly discoloration, decay, and weakened structural integrity. This article will discuss the causes of mold growth, the mistakes to avoid, and the best ways to treat and remove mold from lumber products.

Causes of Mold Growth

Mold reproduces via the production and dispersion of small pores. They are smaller than the seeds of plants and are easily spread through wind and water. They will only start to grow once they land in an environment with the right water, food, temperature, and oxygen.

The perfect mold conditions are:

- Temperature- Mold grows best between 77- and 86-degrees Fahrenheit. It is even better if it is humid.

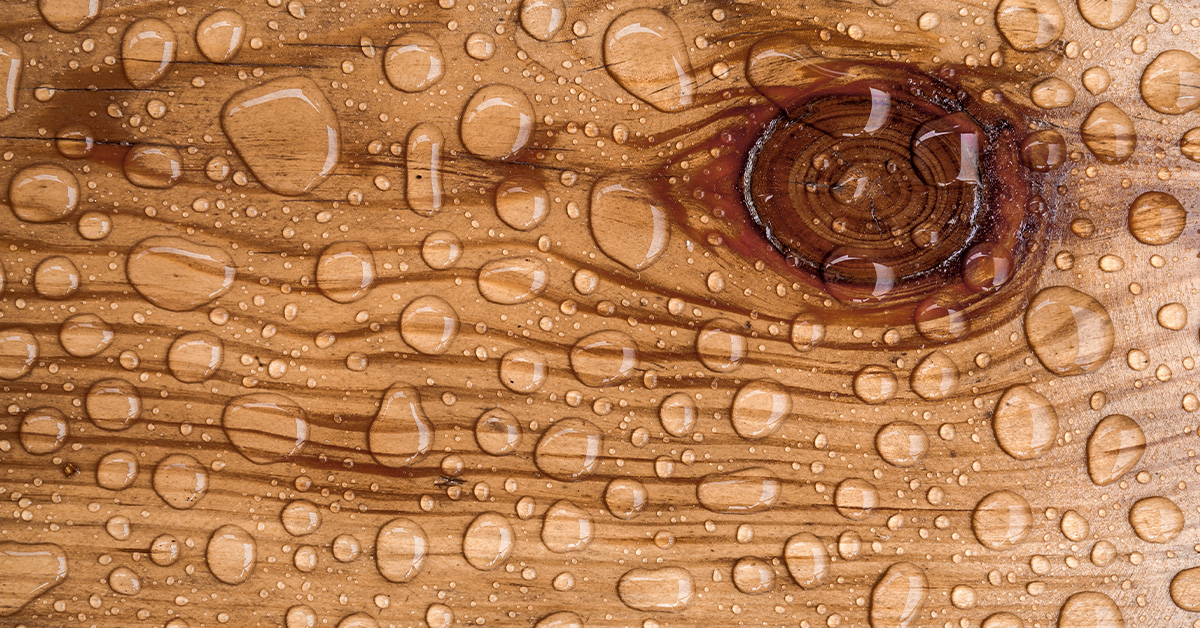

- Water- Mold does its best in damp, humid, and wet conditions. It requires water to spread, which is why it is recommended to keep wood products as dry as possible.

- Oxygen- Mold requires oxygen to survive because they are obligate aerobes. They can grow at very low concentrations of oxygen, so limiting oxygen is not the best way to prevent spread.

- Food- Mold must be on a material that it can digest. It can metabolize virtually any organic matter. Lumber and wood products are prime candidates to be mold’s food source.

Mold Mistakes to Avoid

Now that you understand why and how mold forms, let’s talk about the ways that you can keep your wood products in great condition. Here are the mistakes to avoid:

Not Having Proper Ventilation

Proper ventilation is essential to prevent mold growth, as it helps to keep moisture levels in check. Lumber products should be stored in well-ventilated areas with good air circulation to prevent damp conditions.

Not Practicing Good Storage

Lumber products should be stored off the ground with a protective covering to prevent direct contact with soil or concrete. Avoid stacking lumber products too closely together or in areas where there is poor airflow.

Not Keeping Lumber Dry

It is crucial to ensure that lumber products are always kept dry. Any moisture that enters the wood should be dried as quickly as possible to prevent mold growth. Using kiln dried wood can help to prevent mold because it is completely dried out before being used for manufacturing purposes.

Not Using Mold Inhibitors

There are many environmentally friendly mold inhibitors on the market that can be used to prevent mold growth on lumber products. These products are safe for the environment and human health and are effective at controlling mold growth.

Treating and Removing Mold

Though the best treatment for lumber products is prevention, if you find mold on your wood products there are steps that you can take.

1. Pressure Wash Lumber

Pressure washing is a good first step in treating mold found on pallets and crates. You can use a diluted bleach solution that will help to sanitize and kill the mold on the surface. Make sure that your customers don’t have any issues with chemicals being used on pallets.

2. Kill the Mold

It is hard to completely kill mold that has already infiltrated lumber. The bleach solution above and other chemicals are more likely to kill mold on the surface without getting to the root of the problem.

The best solution is to completely dry out wood once a chemical solution has been used. Mold cannot survive with a moisture content level below 19%. After cleaning the wood, get it to a low moisture content to kill the rest of the mold that might not be easily seen. Once dry, keep them dry to prevent the mold from returning.

3. Replace Damaged Areas

If the mold has caused significant damage to the lumber, it may need to be replaced. Replace any affected lumber products to prevent further damage.

Conclusion: Prevention is Key

The best way to avoid wood mold is to keep it out of the elements and away from water. Water is the number one enemy when it comes to mold growth. Taking care of your lumber by using kiln dried lumber, storing it in good ventilation, and keeping it away from water will give you the best chance possible.

The last tips and tricks we have are:

- Avoid recycled pallets because they may contain mold that you cannot see.

- Work with a trusted wood supplier, so that you are getting the products in good shape, to begin with.

- Properly store your products in accordance with the type of environment and elements they will be exposed to.

- Avoid water at all costs! If they get wet, dry them immediately.