It’s a question that often comes up when you buy pallets. Should you choose new wooden pallets, recycled pallets, or remanufactured pallets to meet your supply chain needs? While the final decision may simply come down to cost, it’s important to know the difference and fully understand what you’re paying for when you buy pallets.

Let’s talk about each of your wooden pallet options and explain the differences.

Recycled Pallets

The world of recycled pallets can be a bit confusing if you don’t understand the industry lingo and have a clear understanding of what to expect in a wooden pallet that’s been recycled.

To begin with, recycled pallets go by a lot of different names:

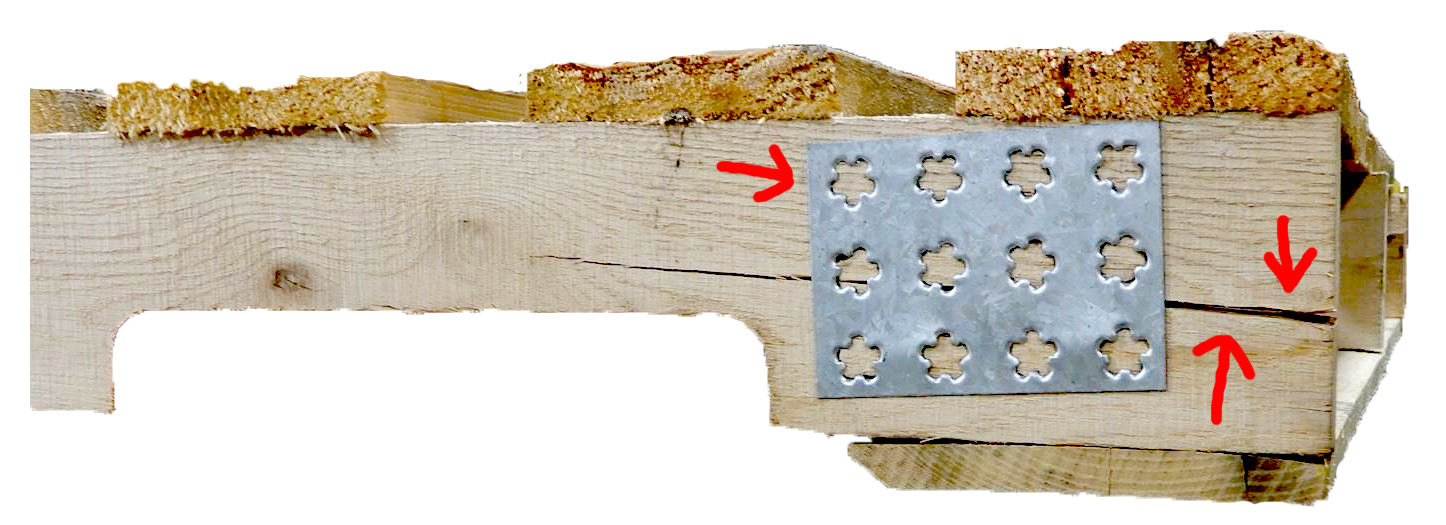

No matter what a company chooses to call its recycled pallets, it still amounts to a pallet that is used over and over again until it reaches the point when it can no longer be repaired. While in use, a recycled pallet will be repeatedly repaired by replacing, plating, or plugging deck boards and stringers so that it can maintain its integrity and remain structurally sound.

The vast majority of recycled pallets are 48 x 40 pallets, also known as standard pallets or GMA pallets. This standard pallet size was established by the Grocery Manufacturers Association, now known as the Consumer Brands Association. Even though the company’s name has changed, “GMA pallet” is still the preferred name for the standard-sized pallet. These GMA pallets have notched stringers, seven boards on top, and five boards on the bottom. If you need to buy pallets that are a custom size, then you probably won’t find them in the recycled market, but there are other standard sizes you can also find:

Recycled Pallet Grades

Recycled pallets are also graded based on their condition and the types of repairs they have undergone. The grade of the wooden pallet not only gives you an idea of what to expect in the way of repairs and condition, but the grade of the pallet usually dictates the price when you buy pallets.

In general, GMA recycled pallets are classified as either A, B, or C. Here’s what each of those grades means:

In addition to the basic recycled pallet grades above, each grade of pallet can be further broken down into grades like 1A, AAA, 2A, etc. Each recycled pallet vendor has its own way of marketing its grades of recycled pallets. The higher the grade, the more expensive the pallet.

For example, when you buy pallets that are Grade 1A, you can expect the following characteristics:

Pros and Cons When You Buy Pallets That Are Recycled

The biggest advantage of using recycled pallets is the price. You may save as much as 70% over new pallets and up to 50% over remanufactured pallets when you buy pallets that are recycled, depending on the grade. If you buy a lot of standard-sized pallets, that can translate into huge savings for your organization.

Unfortunately, there’s also a pretty big downside to using recycled pallets – they fail more often than new ones.

That means that you have to not only consider the cost savings of using recycled wooden pallets, but you also have to account for damage in-transit costs. If using recycled wooden pallets means that a significant percentage of your products are damaged due to pallet failure, then are you really saving money?

In addition, a lot of recycled pallet vendors use shortcuts to increase their profit. Here are just a few to watch out for:

Be careful when choosing a recycled pallet vendor.

Another disadvantage of using recycled pallets is that they lack consistency. Recycled pallets originate from dozens of different pallet manufacturers. They may all be the same dimensions, but board thicknesses, fasteners, and nail placement will likely differ from pallet to pallet. That makes palletizing your product more difficult, so if pallet specifications are important to your supply chain, recycled wooden pallets may not work for you.

Remanufactured Wooden Pallets

Remanufactured wooden pallets, which are also called reman pallets, are wooden pallets that are built out of reclaimed pallet parts. In some cases, remanufactured pallets are built out of a combination of both reclaimed pallet parts and new wood materials. There are also several other names for remanufactured wooden pallets, such as:

Remanufactured pallets can be custom built to a wide variety of sizes, but are generally limited by the initial size of the recycled pallet wood. In other words, if the notched stringers are only 48 inches long, then the configuration of the remanufactured pallet must work with that length too (unless you buy longer stringers made with new wood – which also adds to the cost).

Remanufactured wooden pallets offer a lot of flexibility, but it’s important to choose a good vendor. You need to be able to trust that your vendor is careful about the recycled pallet wood they use (no cracks or splits) and that you’re truly getting what you pay for.

Pros and Cons of Using Remanufactured Pallets

With remanufactured wooden pallets, price and flexibility are your biggest advantages. When you buy pallets that are remanufactured, you can save up to 40% over new pallets. They can also be custom-built to a wide variety of sizes.

Additionally, remanufactured pallet vendors claim that they’re almost indistinguishable from brand new pallets. That may be true, if you can ignore previous fastener holes, discoloration, mold, paint, tar, etc. Remanufactured pallets are not generally pretty.

Remanufactured wooden pallets get their wood from recycled pallets that are dismantled after the wooden pallet has been through enough cycles to be beyond repair. Those wooden pallet parts (along with some new materials) are what remanufactured pallets are made from.

In some cases, that could mean that the pallet wood recovered has already been under stress for a lengthy period of time. When you buy pallets that are remanufactured, you’re completely dependent on the integrity of the vendor to separate the stressed, cracked, or broken wood from the wood that is reusable.

The more recycled wood the vendor can use, instead of buying new material, the higher their profit margin.

Buying New Pallets

There’s not a whole lot of explaining that needs to be done about new wooden pallets. The wood used in new pallets has never been used before, whether on a pallet or some other application. While we can’t vouch for other pallet companies, here at Conner, the wood we use to make pallets comes straight from the mill and has never been used for anything else.

There’s not a whole lot of explaining that needs to be done about new wooden pallets. The wood used in new pallets has never been used before, whether on a pallet or some other application. While we can’t vouch for other pallet companies, here at Conner, the wood we use to make pallets comes straight from the mill and has never been used for anything else.

In addition, when you buy pallets that are new, you can have them custom-designed to fit any product or configuration that you need for your supply chain. New pallets are generally made from #4 grade wood, but you can also have new pallets built out of higher-grade wood if necessary. The most common type of wood used in pallets is softwood, but you can also buy pallets made from hardwoods if needed.

Pros and Cons of Using New Pallets

New pallets will obviously cost more than either recycled or remanufactured wooden pallets. In most cases, the additional cost of new pallets can easily be offset by incurring less in-transit damage and fewer pallet failures than if you buy pallets that are either recycled or remanufactured.

If your organization only uses standard-sized pallets, you’ll need to take a look at your total cost of packaging to see if it makes sense to buy pallets that are new or go with another option. If you’re using highly customized pallets, you’ll most likely want to go with new pallets.

New wooden pallets can be custom built to any size you need and can be specifically engineered to meet your supply chain needs. When you buy pallets that are new, your wooden pallets have consistent quality, making it easier to palletize your products because each pallet has a predictable surface on which to place products.

When you buy pallets that are new, you know that they haven’t endured the wear and tear of carrying repeated loads. You know that your pallets don’t have cracks that are hidden from sight underneath deck boards or on the inside of stringers where you can’t really see them. You also know that the pallets you’re using have been built specifically for your organization, according to your specifications, and have proper nail placement and an appropriate number of fasteners for your product load.

When you buy pallets that are new, you know that they have the strength and durability to support your loads. With recycled pallets, you often don’t know about missing nails or cracks until the pallet fails and your product is damaged.

Lastly, new pallets are always clean and free from the myriad of contaminants that you may find on recycled and remanufactured pallets. Food spills, tar, chemicals, and residue from previous products are all commonly found on recycled and remanufactured pallets.

Molds are almost always found on recycled and remanufactured pallets as well. While mold can be an issue with any wood product, when you buy pallets that are new, you can work with your manufacturer to make sure that new pallets are completely free from mold and stored inside to prevent mold from forming. When any part of a wooden pallet is made from recycled wood, it’s very difficult to guarantee that it’s mold-free because most recycled pallets have been stored outside during their lifetime. On top of that, most pallet recyclers can’t track the history of their pallets so that they can meet inspection standards or be certified.

With new wooden pallets, none of that is a problem because they’re… well… new. If being mold-free or the aesthetics of the pallets are important to your organization, then new pallets are probably your best option.

Wrapping It Up

Hopefully, this long explanation helps clear up the differences between recycled, remanufactured, and new pallets. When you get ready to buy pallets for your supply chain, it makes sense to explore your options for wooden pallets. Once you have a clear understanding of what you can expect from each type of pallet, your choice of pallet should be pretty obvious.

If cost is your biggest concern, then be sure that you’ve considered your total costs, including the costs associated with damage in transit.

*Updated 5/27/2022*

![[PRESS RELEASE] Conner Industries Announces Major Guardian Packaging Expansion](https://conner.b-cdn.net/wp-content/uploads/2024/10/Guardian-Packaging-Expansion-500x383.jpg)

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)