From Dallas to Dublin, wood packaging makes its way across the world, but not without ISPM 15. With millions of pallets, crates, and other wood packaging products circling the globe every day, there has to be protective measures to ensure that all of that wood is being handled responsibly.

That’s where ISPM 15 comes into the picture.

What is ISPM 15?

In order to fully understand ISPM 15, its helpful to know what exactly ISPM is. Don’t you just love regulatory talk?

The International Standard for Phytosanitary Measures (ISPM) is a set of international guidelines that regulate the health of international trade. As we all know, each country has its own culture of sanitation, different flora and fauna, and different issues it has to face. ISPM’s job is to make sure that goods being shipped from one country to the next pose minimal risk to overall global health.

ISPM No. 15, more commonly referred to as ISPM 15 or ISPM15, is responsible for the “regulation of wood packaging material in international trade.”

ISPM 15 is one of many regulatory measures adopted by the International Plant Protection Convention (IPPC), a 1951 multinational treaty overseen by the United Nations Food and Agriculture Organization. IPPC’s goal is to control and prevent the spread of pests in plants and plant products.

More than 130 nations around the world, including the United States, adhere to the guidelines set by ISPM 15. This being said, it’s essential that your export products be ISPM 15 compliant.

Per ISPM 15 guidelines, all wood packaging must be heat treated in order to rid unprocessed wood materials of natural pests. Just like we don’t like to share germs, we don’t want to share pests either. Untreated packages that arrive in foreign ports are commonly fumigated (without unpacking the product), buried, or incinerated.

Turn up the Heat

Wood products that are destined for a foreign country are required to undergo a heat treatment process per ISPM 15 requirements. Heat treating raw wood products is essential to exterminate any possible pests that may be calling a wood packaging product home.

ISPM 15 has very specific guidelines in what exporters are required to do in regard to heat treatments. The wood’s internal temperature must reach a specified heat, bark must be removed from the wood packaging product, and, if fumigating, the air in the chamber must reach a specific concentration of the chemical used. When using chemical fumigation, the concentration differs based off of which chemical is chosen. Luckily, Conner takes care of this process for you.

Heat treatment can be taken care of in many ways under ISPM 15. Approved vendors can choose to chemically fumigate, microwave (not the kind in the kitchen), kiln-dry, and more.

Almost all wood packaging must undergo this heat treatment process. Whether it’s pallets, crates, hardwoods, softwoods, load boards, or dunnage, if it contains wood, it needs to be ISPM 15 compliant. Although this encompasses the vast majority of wood packaging products, there are a few exceptions. Both plywood and oriented strand board are ISPM 15 exempt because they are processed wood products. The processes in which these materials are made naturally irradicates the pest in which ISPM 15 is designed to rid.

Wood Packaging Passport – The Stamp

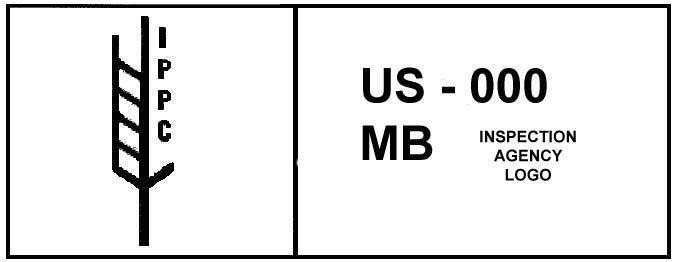

Known to some as the ‘wheat stamp,’ the ISPM 15 stamp is the international indicator that a wood packaging product is ISPM 15 compliant. This stamp can only be issued by approved vendors, and Conner is one of them.

Known to some as the ‘wheat stamp,’ the ISPM 15 stamp is the international indicator that a wood packaging product is ISPM 15 compliant. This stamp can only be issued by approved vendors, and Conner is one of them.

In the United States, approved vendors are regulated by accredited inspection agencies that answer to the USDA.

The stamp looks like a sheaf of wheat on the left-hand side and has letters that indicate the way it was heat treated on the right. On the bottom right-hand portion of the stamp is the logo of the inspection agency that approves the vendor that applies the stamp.

The ISPM 15 stamp itself can be applied with either an ink stamp or a brand. Regardless of which method is used in application, the stamp itself must be easily visible and identifiable on the wood packaging product. Once a stamp is applied, the wood packaging product as a whole is considered to be ISPM 15 compliant for the remainder of its lifespan.

Although this is true, it comes with its own set of caveats.

Any product that is remanufactured or altered in any way must be heat treated again. If this occurs, the old stamp must be removed and a new one must be applied by an accredited vendor.

Wrapping it Up

While understanding the ISPM 15 stamp regulations can be a little confusing, especially when it comes to understanding how those regulations should be applied to your particular situation, we’ve put together an ISPM15 FAQ that will help clear things up. With more than 85 countries implementing the guidelines, it’s definitely not something you should overlook.

Get in touch with us if we can help you with your export packaging needs.

![[PRESS RELEASE] Conner Industries Announces Major Guardian Packaging Expansion](https://conner.b-cdn.net/wp-content/uploads/2024/10/Guardian-Packaging-Expansion-500x383.jpg)

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)