The US lumber industry has played a pivotal role in the American economy for hundreds of years. For those of us who trade lumber daily, it can be easy to forget just how important the role of US lumber has been throughout the history of our country and continent.

Today, let’s take an extensive look at the history, trends, and technology that have made the lumber industry into what it is today. With a history that stretches back over 400 years, it can be intimidating when doing your research – luckily, we’ve broken it down into six different periods that make the history of US lumber a bit more palatable.

Pre-Colonial US Lumber

Although this period isn’t necessarily about “US” lumber quite yet, it’s necessary to cover it to understand why the US lumber industry grew and expanded the way it did. This rapid growth happened because of a series of unique events – almost of all which pertained to Europe.

Before the colonization of the Americas, Europe’s lumber situation wasn’t looking too bright. With many European powers rapidly growing their empires, many of the forests throughout the European continent were massively depleted. Specifically, the British Isles were losing their forests at an unprecedented rate – a rate so high that the UK is still attempting to reforest its lands in the 21st century. All of that being said, a new source of lumber was desperately needed for Europe to continue to expand, something they were dead set on doing.

In 1607, the true start of the US lumber industry began. As we touched on in our pine lumber article, the first documented case of US lumber harvesting happened soon after in the Jamestown settlement. Unfortunately for Europe, the Starving Times brought about the end of Europe’s newfound source of US lumber and the settlement as a whole.

Although this was certainly a setback, several more settlements were established soon after and began producing lumber for Europe once more. As these settlements grew and expanded, so did the European needs for American lumber.

Thirteen Colonies Filled With Lumber

As the European powers established settlement after settlement, the towns and fledgling cities eventually became the 13 American colonies… In large part, the colonies had US lumber to thank for their growth. During the 1700s, European empires put a large emphasis on the building of their navies, a classical arms race if you will. For the British Empire, the raw materials and US lumber needed to support a large navy could be found on the east coast of the American Colonies.

Producing masts and other naval stores was no easy task, every one of the 13 colonies was producing US lumber products for the British navy – take North Carolina for example. According to researchers at NC State, by 1720 the colony was producing over 50,000 British pounds worth of lumber for the navy annually. Although this may not sound like much from a modern perspective, adjusted for inflation, that’s between 3.5-4 million USD! For a newly established economy, this was a huge source of income.

As the colonies continued to grow and expand, more US lumber was needed to help grow the colonies and continually export – leading to mass harvesting of forests throughout the colonies.

A New Nation Built with US Lumber

Toward the end of the 18th century, after America gained independence from Great Britain, many lumber professionals began to realize that the forests that they once thought were limitless, now began to dwindle. Luckily, there was much more US lumber to be found in the West. As more settlers migrated across the continent, new forests brought new opportunities.

Settlers in the upper Midwest found that the Great Lakes region was full of both hardwood and softwood species that were ripe for harvesting. In the South, more and more people discovered the benefits of the vast pine forests that occupied the land there. This US lumber built houses, wagons, crates, skids, tools, and more for the settlers. With so much lumber, and at the time few settlers, the country began to export more and more lumber from the frontier. After all, there was a whole new nation to build.

With every new settlement established going westward, a sawmill was one of the first structures to be built. Lumber was needed for almost every tool and building – unfortunately, these sawmills were still relatively slow and required a lot of manpower to get the lumber cut. It wouldn’t be until later technological advances that sawmills would improve.

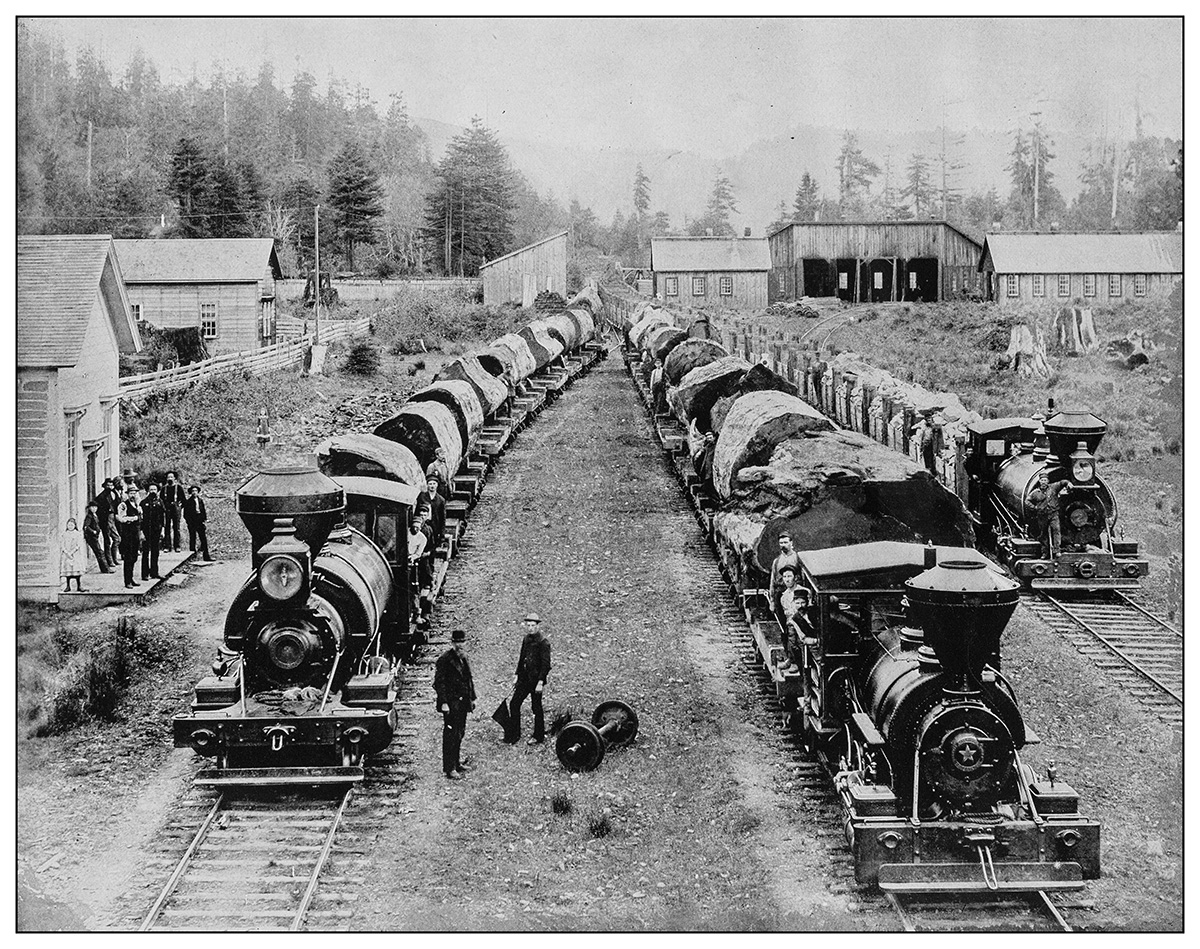

Manifest Destiny, New Technologies, and More Wood!

By the mid-19th century, hundreds of thousands of American settlers were heading west, and there were certainly more to come! What would happen over the next 50 years would eventually be taught to every school-age child as Manifest Destiny. What isn’t typically taught, however, is how US lumber was an extremely large driver of this migration. Between mass migration and immigration, new technological advances, a civil war, and a growing population, more and more US lumber was needed. All of these different factors eventually drove the lumber industry to innovate many of its technologies.

The biggest advancements would come not from how lumber was being used, but from how US lumber was being initially processed. With the advent and increasing popularity of the steam-powered sawmill, lumber processing became a much more fine-tuned process. This increased efficiency at the sawmills, as well as the speeds at which US lumber harvesting and construction could go.

Along with the increased efficiency of sawmill machinery, Thomas Edison’s lightbulb had a major impact on the US lumber industry as well. With the adoption of lightbulbs and electricity at major sawmill locations, workers were able to continue working even in with minimal daylight. Although it may seem like a simple advancement to us, US lumber professionals at the time saw massive benefits from this technological evolution.

Twentieth Century Advancements

As the United States entered the 20th century, the US lumber industry began to rapidly change at a pace that had never before been seen. The introduction of gas-powered vehicles changed the way the industry did every aspect of the business. Rather than using skid rows and rivers to transport logs from remote areas, the popularity of trucks slashed the time and manpower needed to get logs from one place to another. For the first time, lumber had a quick and expedient way of going across the nation without the use of boats. Even more than this, as American roadways developed, American lumber companies were able to use transportation routes never imagined in the past.

By the early 1900s, the West had nearly been won… although there were still fairly large remote regions in the Pacific Northwest with plenty of lumber to go around. Like a moth to a flame, US lumber professionals set up shop in the remote forests of Oregon and Washington to harvest some of the last virgin forests left in the nation. Throughout the early to mid-20th century, the US lumber industry would learn how centuries of logging have affected forests across the nation.

A New Era for US Lumber

Becoming a popular argument in the 1960s and ‘70s, deforestation had become a widespread argument against the lumber industry. At this point, settlers, colonists, and citizens had been harvesting US lumber for well over 300 years without any sort of reforestation efforts. It turns out, the once limitless forests of the American continent weren’t so limitless after all – The American lumber industry needed to pivot into a more sustainable direction.

By the 1980s and ‘90s, the US lumber industry started to correct the issues that had been brought up in recent years. Due to scientific advancements and a deeper understanding of the US lumber that we use, industry professionals developed sustainable harvesting practices to ensure that the lumber industry would be around for years to come. Rather than slashing down large swathes of forests at a time, lumber companies began to invest in the replanting of trees. This allows timber companies to harvest in cycles, creating a sustainable model for the future of US lumber.

The Story of US Lumber Continues

With such a rich history, it’s hard to fill the shoes of the industry’s predecessors. Fortunately, modern-day US lumber innovators continue to drive the industry forward with new technology, techniques, and methods. Although portions of the industry’s past may not have been bright, the future continues to look more and more promising as we continue to learn about the sustainable, reliable, material that is US Lumber.

![[PRESS RELEASE] Conner Industries Announces Major Guardian Packaging Expansion](https://conner.b-cdn.net/wp-content/uploads/2024/10/Guardian-Packaging-Expansion-500x383.jpg)

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)